AEROCOMPACT rocks the solar market

PV mounting system expert AEROCOMPACT has developed COMPACTPITCH XM-F REPTILE, a universal solution for pitched roofs that can be used with a wide variety of roof tiles. "With our new system, we are rethinking tile solutions and establishing our pioneering role in innovative substructures," explains AEROCOMPACT product management manager Albert Vonbun.

Highest load-bearing capacity

AEROCOMPACT's latest innovation replaces expensive and inflexible sealing components with an integrated solution:

Since the cover plate is positioned independently of the fastener unit, it can always be installed above the rafter, and transfers the resulting forces directly into the roof structure.

The patent-pending labyrinth-style seal ensures that the breakthrough point, which can be selected as desired, provides a permanent seal during installation without requiring any additional effort.

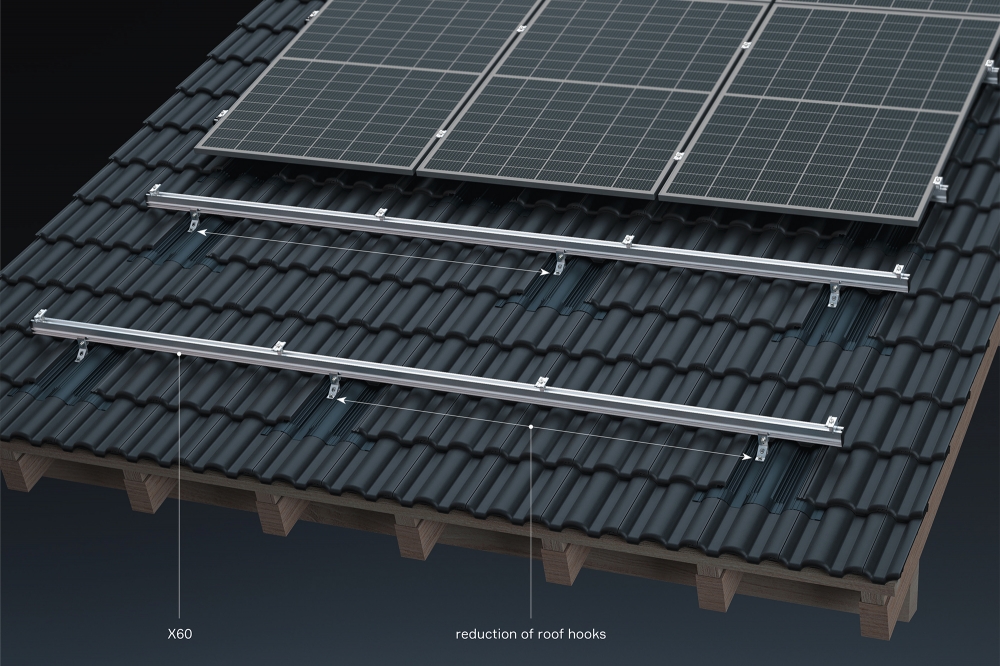

Due to the high load-bearing capacity, this in combination with the new and strong X60 rail – lowers the number roof hooks needed, which drastically reduces installation and material requirements and costs. Since the solution transfers forces optimally, even areas with high snow loads are no problem.

Maximum design freedom

The system, which will be for sale starting at the end of July, includes not only the fasteners but also colored cover plates, available in red, brown or anthracite. "There are countless different types of roof tiles on the European market. Until now, installers have had to cut them to size with an angle grinder for the PV mounting system to fit," explains AEROCOMPACT product management manager Albert Vonbun. Doing this, however, means a great deal of work and the risk of breaking the tile. In addition, positioning the fastener is dependent on the tile, so the forces are not optimally transferred via the rafter into the roof structure

"With our solution, we are setting new standards in terms of sealing and flexibility. Our cover plate replaces a roof tile and can be independently positioned and easily adapted to the contour of the surrounding tiles without the need to machine them." Thanks to the pre-mounted assemblies, installation is quick and easy with just one tool.

Quickly assembled

First, the base plate is screwed onto the rafter and the carriage is fixed in the appropriate position. Then the cover plate can be freely placed on the carriage and adjusted along the tile contour. The appropriate place for fixing the roof hook can be marked with a slight pressure of the thumb. The pre-assembled hook is fastened with two thin sheet metal screws. Depending on the roof batten height, the carriage can be attached at three different heights. Fine adjustments of the latched X-rail are possible with the preassembled quick connector.

Thanks to the pre-assembled modules, installation is quick and easy with just one tool. "Overall, we reduce assembly time by up to 40 percent," says Vonbun.

Optimized force transmission

The resulting forces are transmitted directly into the roof structure. The high load values make it possible to reach spans of up to 1.4 meters between the roof hooks, which means that far fewer hooks are needed than would be the case with conventional systems. High snow loads are, therefore, no longer a challenge for the extremely stable system.